DUPLOFANI ZA LEPLJENJE KLISEA

proven benefits - Always a Fitting Solution: tesa Softprint®

At tesa, we offer a wide assortment of Softprint® plate mounting tapes for different requirements

regarding foam hardness, adhesive properties, and tape thickness.

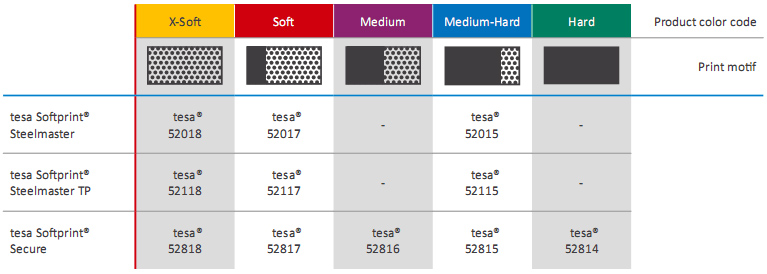

Narrow Web: tesa Softprint® 380 µm/15 mil

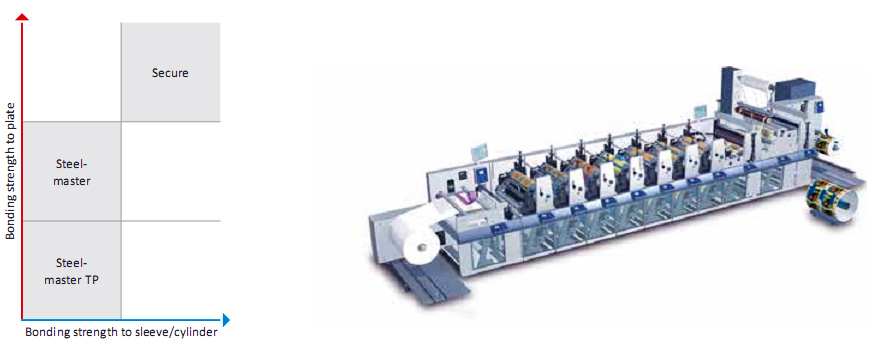

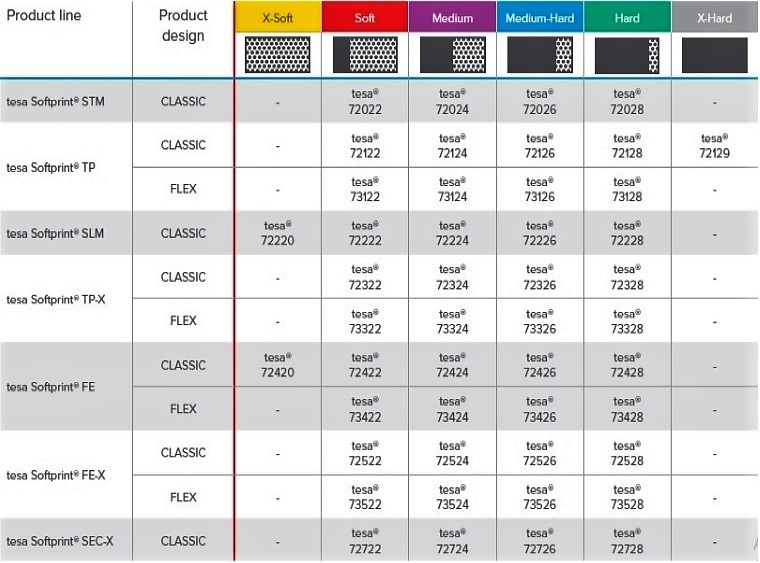

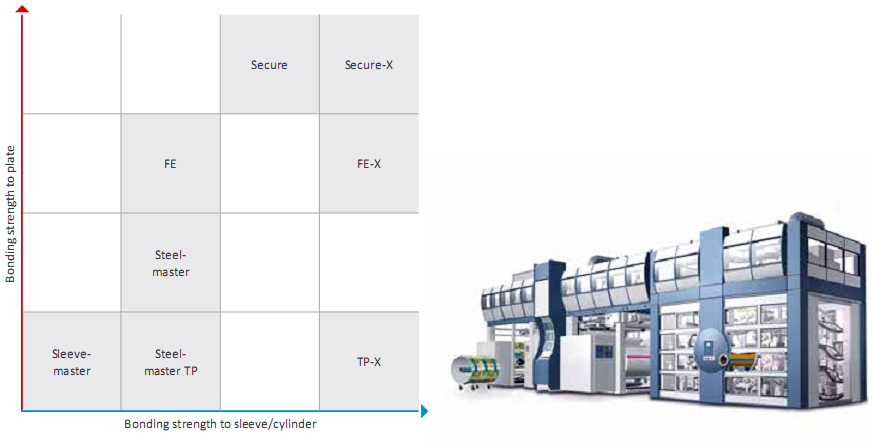

Different requirements regarding bonding strength to cylinders and plates call for different adhesive solutions.

Distinctive product lines for flexo printers offer the appropriate solution for each requirement.

Wide Web: tesa Softprint® 500 µm/20 mil

Our products prove their impressive quality day in, day out in demanding conditions and are regularly subjected to strict controls. All information and recommendations are provided to

the best of our knowledge on the basis of our practical experience. Nevertheless, we can make no warranties, expressed or implied, including, but not limited to any implied warranty

of merchantability or fitness for a particular purpose. Therefore, the user is responsible for determining whether our product is fit for a particular purpose and suitable for the user’s

method of application. If you are in any doubt, our technical staff will be glad to support you.

Tips for Optimum Plate Mounting

Cleaning

All elements should be handled at room

temperature – or at least at equal

temperatures.

Clean back of new or used plate of dust,

grease, or other contamination using a

suitable solvent.

Clean per manufacturer recommendations

and wipe dry with clean cloth.

Mounting

Apply the tape in a sweeping motion,

line by line. Use a squeegee for best

results.

Only fix the plate on a narrow area

of the tape. Avoid premature contact

between plate and tape by using

liner material.

on the leading and trailing edge. This

will give a better bond than just by hand.

Demounting

Plate and tape demounting

Remove plate first, then remove the

tape slowly at a flat angle.

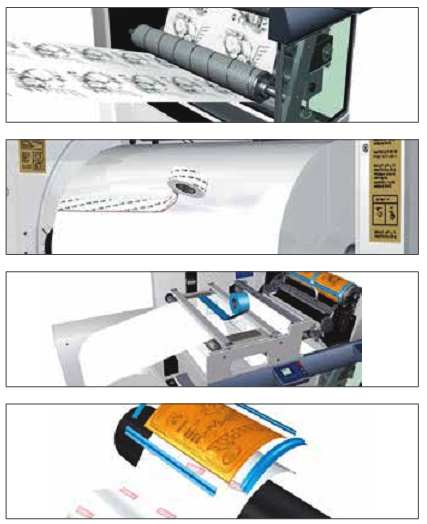

Our Complementary Products for Flexographic Printing

Roller wrapping tesa® 4863, tesa® 4563

tesa Printer’s Friend® roller wrapping tapes offer outstanding

“grip” and repel a variety of substances involved in the

process (e.g. adhesives or inks)

Flying splice for film materials tesa® 51910

tesa® 51910 EasySplice® FilmLine PLUS enables manufacturers

and processors of thin, high-slip films to save time and money

by splicing at continuous production speeds.

Zero-speed splice tesa® 4104, tesa® 4137

Sufficient adhesion and shear strength for splicing of all

materials, including alternatives for higher temperatures.

Edge sealing tesa® 4244 PV2, tesa® 4287

The adhesives stick on photopolymer plates and are

subsequently easy to remove without leaving residues.

For marking material imperfections or print faults. This can

be done separately due to a selection of available colors

End tabbing tesa® 4124

To prevent unwinding of finished rolls we offer tapes with

safe bonding on all substrates. Available in brown, white, and

transparent.

Core starting tesa® 64621

Excellent adhesion properties to ensure the web is securely

fixed to the core.

Supportive tools

We also offer supportive tools such as cleaning rollers, rubber

rollers, and adhesion promoters to make several process

steps more efficient and easie

TESA TRAKE

Grafohem d.o.o. je zastupnik i distributer vodećeg svetskog proizvođača lepljivih traka Tesa Tape - Hamburg,

koja sa asortimanom preko 6000 proizvoda osigurava da naši korisnici dobiju prilagođena i inovativna rešenja.